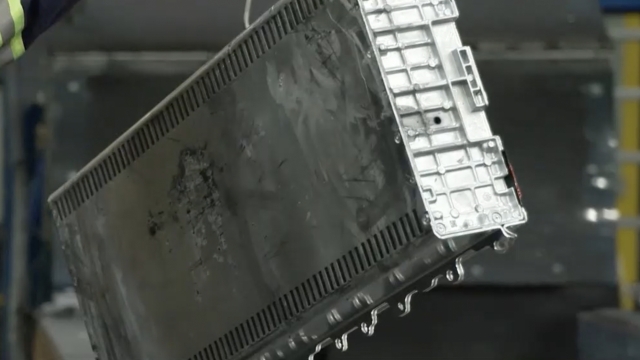

A conveyor belt at the Ascend Elements electric vehicle battery-recycling plant in Covington, Georgia, moves lithium-ion EV batteries down the shredder line one at a time.

Most of the batteries are the result of electric vehicle recalls and have been sent to Ascend from car dealerships or battery manufacturers.

"Those boxes, that's where we remove all the energy from the batteries," said Scott Plickert, the general manager at Ascend Elements.

Once discharged, the batteries or modules are ready to be ground up.

The result? Plickert says they're able to collect the infinitely recyclable materials found inside each battery.

"You have plastic, you have aluminum, you have copper, you have nickel and this highly coveted powder called 'black mass,'" he said.

SEE MORE: Electric vehicle market could be in for a bumpy ride

It's all material that can be reused in the same industry, which is cost-effective. It helps to cut down on the need to mine these so-called "rare earth minerals" out of the ground, which are oftentimes sourced overseas from China.

Each electric vehicle you see out on the road contains anywhere from four to eight modules. Packed together, they make one large battery-pack to power your EV for anywhere from 10 to 20 years.

Ascend's Georgia plant alone has the capacity to recycle 30,000 tons of battery material and scrap each year. That's the equivalent of enough batteries to power 70,000 electric vehicles.

"We're not only keeping these batteries out of landfills, but we're also harvesting that material to put back into the supply chain, because there is such an incredible demand for electric vehicles right now. So that helps lower the carbon footprint of new electric vehicle batteries," said Thomas Frey, senior director of Ascend Elements.

And Georgia isn't the only state contributing to the effort to recycle EV batteries. Other companies are already operating similar facilities in Arizona and South Carolina.

Ascend Elements is planning to expand. It's currently building its fourth plant in the U.S. — a $1 billion facility in Hopkinsville, Kentucky, expected to open in 2024.

Trending stories at Scrippsnews.com